NEW STUDENTS-

- YOU MUST WATCH A RECORDED ZOOM ORIENTATION, AND THEN ATTEND A 1-HOUR IN-PERSON ORIENTATION TO GAIN

ACCESS TO SHOP SPACES.

STUDENTS WHO HAVE NOT COMPLETED ORIENTATION (AND SUBSEQUENTLY BEEN FREQUENT SHOP USERS) WITHIN THE PAST

2 YEARS MUST AGAIN TAKE ORIENTATION SESSIONS.

PLEASE EMAIL archshops@mit.edu WITH QUESTIONS.

Once students complete orientation sessions, they are granted card access to the building 3 shop spaces,

and are allowed to use N51 when staffed, as well. A limited range of self-service work is approved upon completion of

shop orientation.

However, shop users must get training on all machines, tools, and processes

that they are not well-trained and recently practiced in - experience in other shops does not automatically

qualify as relevant or sufficient experience in this shop.

Shop users are added to a webmoira email list (laser-users@mit.edu) which we use for all general shop-related

communication.

Users are expected to read and understand (or ask about) all communication from shop staff.

To contact us for any reason (questions are always encouraged), users should email archshops@mit.edu. Emailing

individual staff is allowed, but usually much less efficient.

UNTIL FURTHER NOTICE, COVID-RELATED PROCEDURE MUST BE FOLLOWED TO RETAIN SHOP ACCESS - SEE

MORE DETAIL ON ABOUT PAGE.

Shops are currently open only during staffed weekday time blocks, which are reflected on the individual shop room schedules/sign up

sheets (see ABOUT page). Curricular shop use (as well as studio use) is only allowed during these blocks,

and shops are required to be staffed for any use within them. Shop users will have card access to building 3 spaces during those time

blocks after completing orientation, and can enter N51-160 when it is staffed (card access to N51-160 is reserved for staff).

More information about current Covid-related use requirements are on ABOUT page.

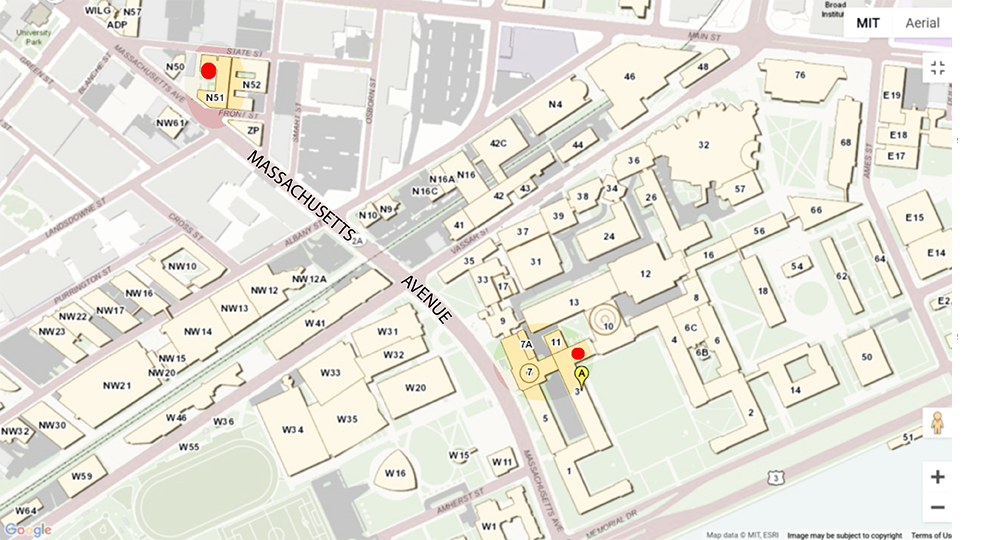

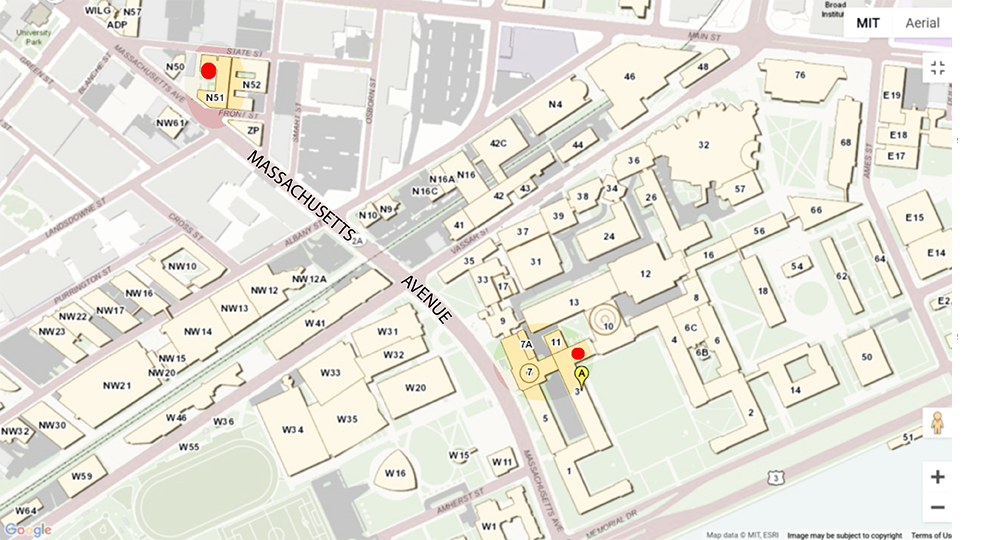

Architecture Shops are in two different locations:

77 Massachusetts Ave, Building 3

and 265 Massachusetts Ave, Building N51

for more detail and shop staff contact info, see ABOUT page

SHOP SAFETY RULES

ALL SHOP USERS ARE REQUIRED TO KNOW AND FOLLOW THESE RULES AT ALL TIMES

-

DRESS APPROPRIATELY -

- NO LOOSE CLOTHING OR JEWELRY, OR OPEN-TOED SHOES

- NO HEADPHONES IN ROOMS HOUSING CUTTING TOOLS/CNC MACHINERY

- TIE BACK LONG HAIR TO PREVENT CATCHING IN MACHINERY AS WELL AS PREVENTING OBSCURING OF VISION

- SAFETY GLASSES, HAIR TIES, AND HEARING PROTECTION CAN BE FOUND IN PPE CABINETS, WHICH ARE INSTALLED IN EACH SHOP ROOM

- SAFETY GLASSES MUST BE WORN IN MACHINE SPACES AT ALL TIMES IN 3-410/N51-160 AND/OR IN ANY SPACE WHEN ANY POTENTIAL SPLASHING OR SHRAPNEL

MAY BE CREATED

- NEVER USE A TOOL OR MACHINE YOU HAVE NOT BEEN CLEARED FOR BY HAVING RECENT TRAINING/TRAINED EXPERIENCE WITH.

ASK SHOP STAFF FOR TRAINING

- NEVER WORK ALONE WITH ANY CUTTING TOOLS OR MACHINES

- MATERIALS MUST BE EXPLICITLY APPROVED OF IN WORKSPACE (SEE "APPROPRIATE LOCATIONS FOR MATERIALS & PROCESSES" TAB)-

CONFIRM WITH SHOP STAFF

- DISPOSABLE GLOVES MUST BE WORN WHEN WORKING WITH ANY NON-WATER-BASED LIQUIDS, AND SHOULD BE WORN WHEN

USING ANY LIQUIDS

- PRACTICE GOOD HOUSEKEEPING. PREVENT SLIP/TRIP HAZARDS, WIPE UP ANY SPILLS IMMEDIATELY. KEEP WORK AREAS

ORGANIZED, AND LEAVE THEM CLEANER THAN YOU FOUND THEN

- DO NOT LEAVE MATERIALS, TOOLS, DUST, OR ANY OTHER DEBRIS BEHIND. ASK ABOUT WIP STORAGE BEFORE STARTING WORK

- FOLLOW PROPER PROCEDURE FOR ALL WASTE DISPOSAL- SEE WASTE DISPOSAL

- DO NOT WORK WHEN TIRED OR DISTRACTED. YOU MUST BE FOCUSED ON YOUR WORK AND YOUR SURROUNDINGS IN THE SHOPS

- ALWAYS ASK FOR TRAINING/HELP, EVEN WITH THINGS THAT ARE FAMILIAR

-

ALWAYS CHECK MACHINE/TOOL SETUP BEFORE USE - SHARED EQUIPMENT SHOULD NEVER BE ASSUMED TO BE READY TO OPERATE

- ALWAYS REMEMBER TO PUT/KEEP MACHINE/TOOL GUARDS IN PROPER POSITION ~BEFORE~ TURNING POWER ON, AND ALWAYS KEEP

HANDS SAFELY CLEARED OF POINTS OF OPERATION

- USE PUSH STICKS OR OTHER TOOLS TO KEEP HANDS SAFELY DISTANCED WHENEVER NECESSARY

- NEVER USE HANDS TO CLEAR MATERIAL SHAVINGS OR DUST

- NOTIFY SHOP STAFF IMMEDIATELY ABOUT ANY TOOL OR MACHINE ISSUE

- NEVER WEAR FABRIC/LEATHER GLOVES WHILE OPERATING ANY MACHINE!

- DO NOT EAT OR DRINK IN THE SHOPS

Whether you have been assigned a project with very specific details, one that is entirely open-ended, are doing self-directed work, or in any other

circumstance, the best time to contact us is at the beginning of your planning process, before you make final decisions about materials or processes,

and definitely before buying anything.

You may end up needing only a 15-second confirmation on one detail, or we may be able to provide a lot more support.

We can help students make material and machine choices much more effectively, estimate potential time and effort requirements for particular choices,

predict and avoid potential issues, and in the end, save time, effort, and funding - if we are brought in early.

Problems typically occur when a

student doesn't ask us for help until they're 80% of the way through a plan that is falling apart. Please don't wait to check in with us, whether you

have specific questions, or don't even know whether there's anything to address. Most likely, there are things we can help with.